<<Previous: FMS – a.1 Buy Plan

Buy Plan Template

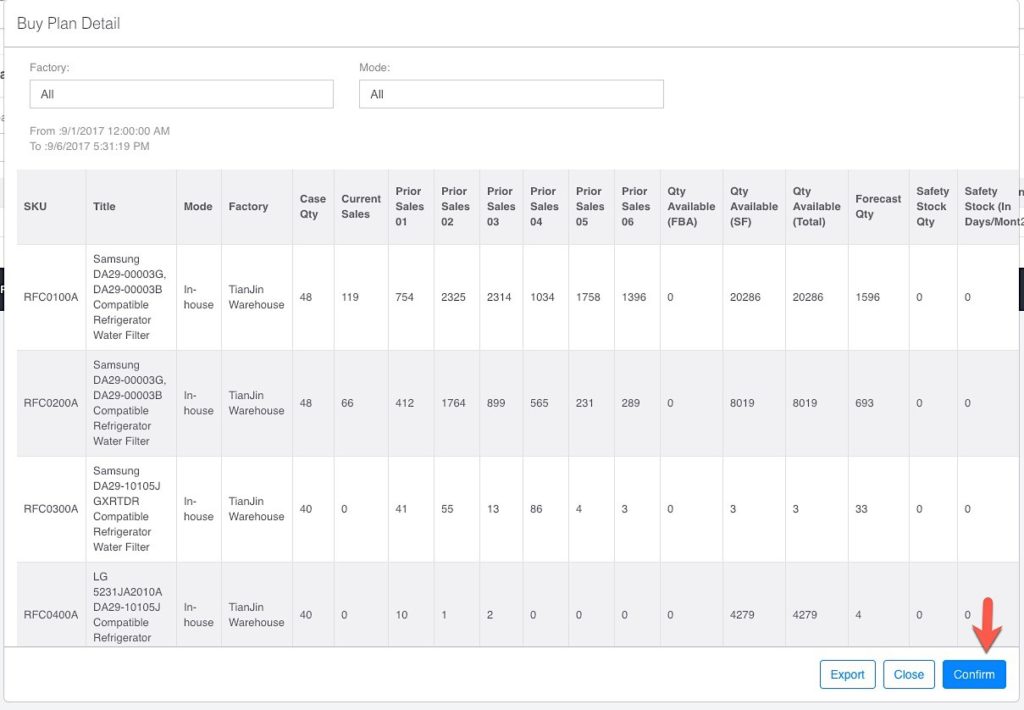

The info below are the data definition for the Buy plan.

-

SKU, Title, Mode, factory & Case Qty: This is the Inventory Product itself. Note that this will not pull in any Raw Materials

-

Current Sales: this will bring in the sales record for the current month that the report is ran for. This field is not used for any calculation throughout the Buy Plan

-

Prior Sales – 01 to 06: This will always be the sales data for the month before the current month. Example, if I ran the report today (in May), the Prior Sales – 01 will be the month of April, the Prior Sales – 02 will be the month of March, the Prior Sales – 03 will be the month of Feb in that order until you get to Prior Sales – 06 before it resets again.

-

Qty Available (FBA): This will pull the total inventory available at FBA for each SKU under the “Product’s Pack” from the “Chanel Product”

-

Qty Available (SF): This will be the total “Sellable” inventory available in every warehouse that the user can see other than FBA

-

Qty Available (Total): This will be the total of Qty Available for (FBA and SF)

-

Forecast Qty: This will be the sum of the “Prior Sales – 01” to the “Prior Sales – xx” that has data greater than 0 divided by count of the number “Prior Sales”. See example on spreadsheet. Results are rounded up

-

Safety Stock Qty: This will be “(Forecast Qty/30)”* “Safety Stock (In Days/Month)”. The Safety Stock (In Days/Month) comes from the setting under the Inventory Product table. The 30 in this case represent the # of days. Results are rounded up

-

Lead Usage Time (Qty): This will be “(Forecast Qty/30)”* “MF Lead & Transportation Time (in Days)”: The “MF Lead & Transportation Time (in Days)”comes from the setting under the Inventory Product table. The 30 in this case represent the # of days. Results are rounded up

-

Order Qty Point: This will be the “Safety Stock Qty + the Lead Usage Time (Qty)”.Results are rounded up

-

Est Qty to Produce: This will be “Order Qty Point – Qty Available (Total). If the result is a negative number, default to 0, if not results are rounded up

-

Qty in Route: This data will come from the PO table, it will be the total quantity (into all warehouse) in route

-

Max Available: This will be based on the BOM data, how many total quantity can be produced.

-

Qty in Production: This is pull from the WO’s that are on “In Progress” status on the production tables below. its left 0 if this criteria is not found

-

Qty to Produce: This will be “Est Qty to Produce – Qty in Route – Qty in Production” If the result is a negative number, its default to 0, if not results are rounded up

-

Qty to Produce (Case Qty): This will look at the Qty to Product and determine how many units per case. Results are rounded up

-

Date Expected: This is pull from the WO’s that are on “In Progress” status on the production tables below. If more than one date is found for the same item, the earliest date is chosen

-

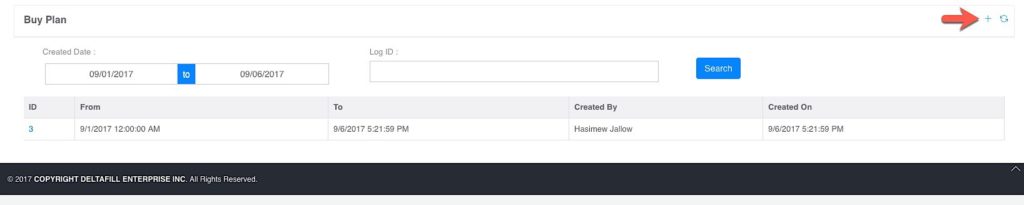

this is used to add/create a new Buy Plan, and click on Confirm to Save the Buy Plan

this is used to add/create a new Buy Plan, and click on Confirm to Save the Buy Plan

-

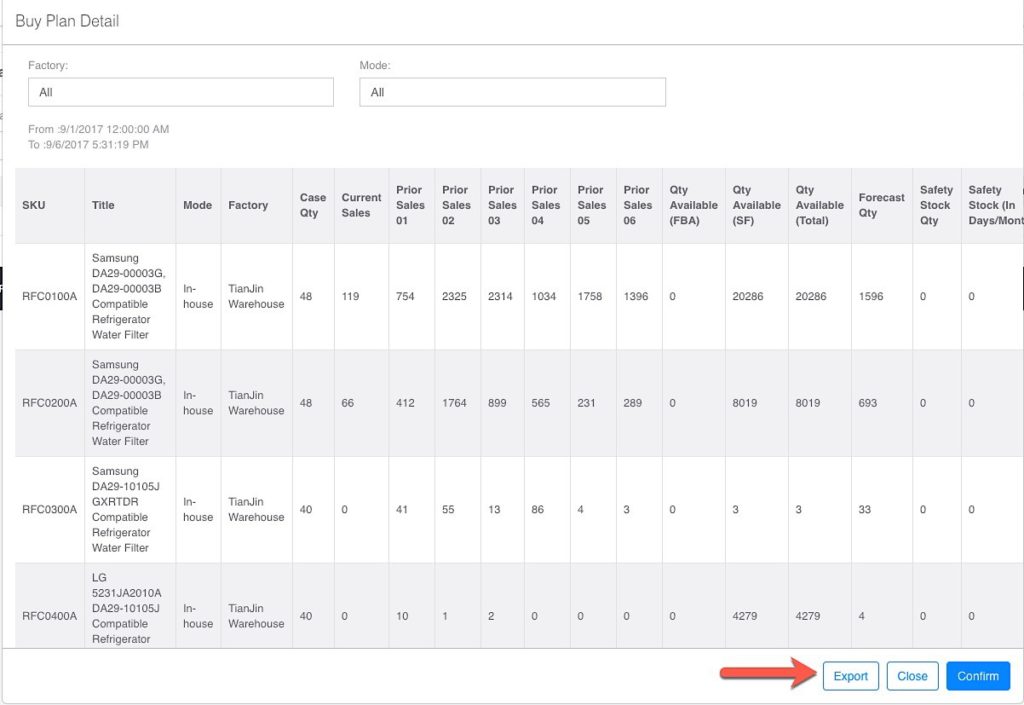

Click on Export to export the buy plan in an excel format, Export will also display all the columns

-

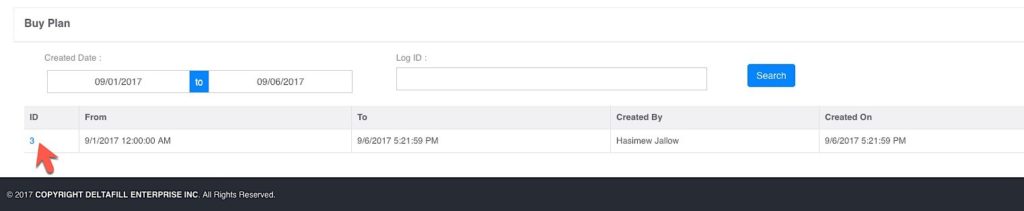

Click on the ID to see previously saved Buy Plan

FMS

a.1 Buy Plan

a.2 Buy Plan – Template

b.1 Production – Build of Materials

b.2 Production – Work Order Schedule(s)

[Table of Contents]